Cumaru Decking

With decades of proven performance in high profile commercial applications, Iron Woods Cumaru is renowned for its natural resistance to everything nature can throw at it. A South American species recognized for its incredible strength and durability, Cumaru can be used in ground contact without preservatives. It’s widely used in commercial applications, such as boardwalk and bridge decking, where large volumes of fixed dimensions and lengths are required.

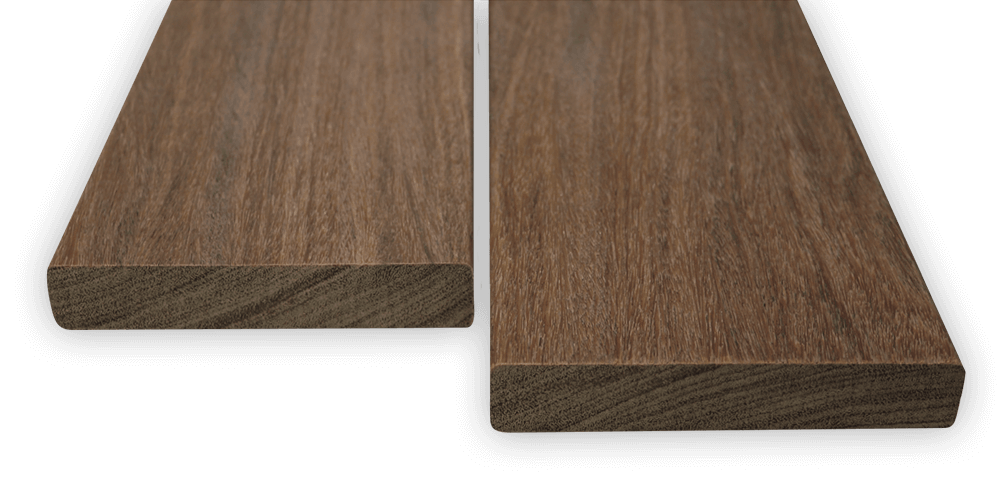

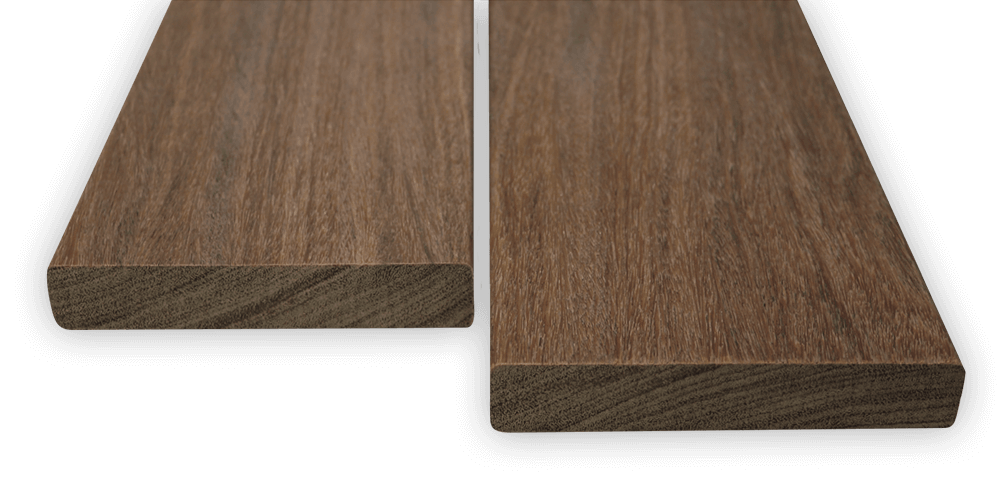

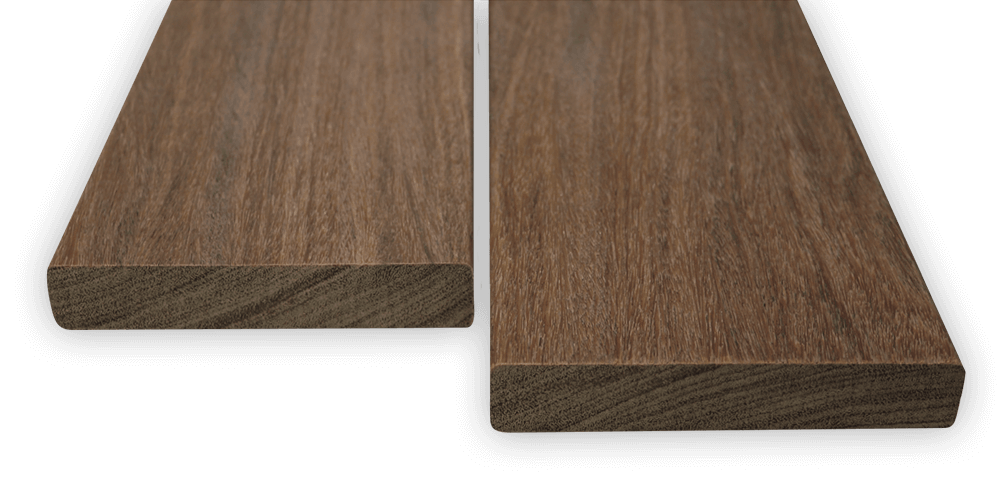

Premium Grade

100% clear all heartwood and graded for appearance on the face, back, and edges. Unsound milling defects not allowed.

Availability

Product availability rough sawn full or nominal dimensions S4S or S4S E4E. See full availability details.

FEATURES & BENEFITS

Why Choose Cumaru?

FEATURES & BENEFITS

Why Choose Cumaru?

Time tested for decades of performance.

Your next project begins with Iron Woods. Let’s get started.

Tell us what you’re looking for.

Your next project begins

with Iron Woods.

Technical Details

Our technical support is unmatched in the industry. Have a question? We’re here to help. Always.

Storage & Handling

- Iron Woods® Cumaru decking is supplied as kiln-dried lumber and is for outdoor use only.

- Store the wood out of direct sunlight and be sure to keep it dry and off the ground.

- Allow the wood to acclimate and stabilize to the installation area’s humidity before installing.

- Cumaru will naturally slightly darken on exposure.

Spans & Spacing

These spans are designed for Cumaru to allow for minimal deflection of the deck surface. Contact us for maximum spans and engineering data.

| Load Size | |

|---|---|

| Board Size | 100 psf |

| 1×4 | 16″ |

| 1×6 | 16″ |

| 5/4×6 | 24″ |

- Allow a 3/16″ gap between 6″ wide deck boards and a 1/8″ gap between 4″ wide deck boards for drainage, airflow and expansion.

- Kiln dried decking may expand 1/8″ on 6″ wide boards during times of high moisture.

- Expect some shrinkage in width in hot or dry areas.

Deck Ventilation

- Adequate ventilation of the deck is essential for long-term stability and to minimize cupping.

- Proper air ventilation allows air to flow in from outside the deck area, under the joists and up through the gaps between the deck boards.

Finishing

- Seal immediately after installation to reduce the potential for surface checking. If installing over a prolonged period or during hot weather, sealing after each phase is recommended.

- Be sure to seal all ends immediately after cutting with Anchorseal clear wax end sealer (available from your Iron Woods® dealer) in order to reduce end checking.

- To maintain a golden brown color, use a transparent, penetrating oil-based sealer with UV inhibitors in a trans-oxide-pigment tint and reapply annually, or as needed.

- If you prefer a natural, silvery-gray appearance, use a clear oil-based sealer for the first coat and then simply let the wood weather to its natural gray color.

- If you want to return silver-gray wood to the original color, use a “wood brightener.” Careful power washing and/or sanding can help to remove the grayed wood.

- “First Coat” Iron Woods® may be available by special order. These orders come pre-finished with “First Coat” for those customers desiring to take the guesswork out of their first application of wood sealant.

Best Practices

- Download a more in-depth, printer-friendly PDF Best Practices Guide.

- Click the link to open/download the PDF in most browsers. You can also right-click and choose to Save Link As.

Technical Details

Our technical support is unmatched in the industry. Have a question? We’re here to help. Always.

Storage & Handling

- Iron Woods® Cumaru decking is supplied as kiln-dried lumber and is for outdoor use only.

- Store the wood out of direct sunlight and be sure to keep it dry and off the ground.

- Allow the wood to acclimate and stabilize to the installation area’s humidity before installing.

- Cumaru will naturally slightly darken on exposure.

Spans & Spacing

These spans are designed for Cumaru to allow for minimal deflection of the deck surface. Contact us for maximum spans and engineering data.

| Load Size | |

|---|---|

| Board Size | 100 psf |

| 1×4 | 16″ |

| 1×6 | 16″ |

| 5/4×6 | 24″ |

- Allow a 3/16″ gap between 6″ wide deck boards and a 1/8″ gap between 4″ wide deck boards for drainage, airflow and expansion.

- Kiln dried decking may expand 1/8″ on 6″ wide boards during times of high moisture.

- Expect some shrinkage in width in hot or dry areas.

Deck Ventilation

- Adequate ventilation of the deck is essential for long-term stability and to minimize cupping.

- Proper air ventilation allows air to flow in from outside the deck area, under the joists and up through the gaps between the deck boards.

Finishing

- Seal immediately after installation to reduce the potential for surface checking. If installing over a prolonged period or during hot weather, sealing after each phase is recommended.

- Be sure to seal all ends immediately after cutting with Anchorseal clear wax end sealer (available from your Iron Woods® dealer) in order to reduce end checking.

- To maintain a golden brown color, use a transparent, penetrating oil-based sealer with UV inhibitors in a trans-oxide-pigment tint and reapply annually, or as needed.

- If you prefer a natural, silvery-gray appearance, use a clear oil-based sealer for the first coat and then simply let the wood weather to its natural gray color.

- If you want to return silver-gray wood to the original color, use a “wood brightener.” Careful power washing and/or sanding can help to remove the grayed wood.

- “First Coat” Iron Woods® may be available by special order. These orders come pre-finished with “First Coat” for those customers desiring to take the guesswork out of their first application of wood sealant.

Best Practices

- Download a more in-depth, printer-friendly PDF Best Practices Guide.

- Click the link to open/download the PDF in most browsers. You can also right-click and choose to Save Link As.

Need to Know

Product Availability

| NOMINAL SIZE | LENGTHS | LENGTHS |

|---|---|---|

| 1" X 6" – 5"/4" X 6" | KD Decking | 8'-20' |

| 2" x 4" – 2" x 6" | AD Dimensional Lumber | 8'-20' |

| 3" x 6" – 3" X 12" | AD Timbers | 8'-20' |

| 4" x 4" – 4" x 12" | AD Timbers | 8'-20' |

| 6" x 6" – 6" x 12" | AD Timbers | 8'-20' |

| 8" x 8" – 8" x 12" | AD Timbers | 8'-20' |

| 10" x 10" – 10" x 12" | AD Timbers | 8'-20' |

| 12” x 12” | AD Timbers | 8'-20' |

PRODUCT COMPARISON

Which wood is right for you?

| Type | ||

| Maintenance | ||

| Decay Resistance | ||

| Termite Resistance | ||

| Strength | ||

| Movement in Service | ||

| Fire Rating Class | ||

| Weight per cu. ft. | ||

| Bending Strength (in psi) | ||

| E-modulus | ||

| Shear Strength | ||

| Hardness |

Got a question about Cumaru?

We’ve got the answers.

From durability and sustainability to maintenance and cost, we tell you everything you need to know about Cumaru.

What is Cumaru decking made out of?

Cumaru decking is made from Cumaru, a dense and durable hardwood that is native to South America, particularly Brazil, Bolivia, and Peru. Cumaru wood is prized for its attractive grain pattern and natural resistance to decay, rot, and insect infestation. It is often used in high-traffic areas such as decks, patios, and outdoor furniture, but it can also be used for interior flooring, cabinetry, and millwork. Cumaru wood ranges in color from light brown to reddish-brown, and it can be finished to a high polish. It is also referred to as a sustainable and eco-friendly wood option, as it is harvested from managed forests.

Is Cumaru wood durable?

Yes, Cumaru wood is highly durable and has excellent resistance to rot, decay, and insect damage and a wide range of environmental conditions. Its Janka hardness rating of around 3,540 pounds-force (lbf) makes it one of the most durable hardwoods available. This means that it can withstand heavy foot traffic, harsh weather conditions, and other outdoor elements with minimal wear and tear.

Cumaru wood is often used for outdoor decking because of its superior durability. Additionally, its natural resistance to moisture and decay make it a popular choice for marine applications, such as dock construction. Cumaru wood is also highly resistant to warping, twisting, and splitting, which makes it a low-maintenance option for a variety of projects.

How long does Cumaru wood last?

Cumaru wood is one of the most durable hardwoods available, with a lifespan of up to 50 years or more with proper care and maintenance. The high density and natural oils in the wood help to resist rot, decay, and insect damage, making it an ideal choice for outdoor use, such as decking, fencing, and furniture.

What are the benefits of using Cumaru for decking?

Cumaru wood is one of the most durable hardwoods available, which gives it excellent resistance to wear and tear. It is also resistant to warping and twisting (which makes it a good choice for flooring and decking) and to rot, decay, and insect damage (which makes it an ideal choice for outdoor projects). Cumaru wood is relatively stable, meaning it is less likely to shrink or expand with changes in temperature and humidity. This makes it a good choice for projects that require consistent dimensions and minimal movement. Cumaru wood is a sustainable and eco-friendly option, as it is harvested from managed forests. Its growth rate is also relatively fast, which makes it a renewable resource.

What are the color variations of Cumaru wood?

Cumaru wood has a range of color variations that can vary based on the specific species and growing region. Generally, Cumaru wood ranges in color from a light golden-brown to a reddish-brown, with darker streaks and highlights. As Ipe wood weathers, it may develop a grayish patina. Some people prefer this weathered look, while others prefer to maintain the wood's original color.

Why type of maintenance does Cumaru decking require?

To maintain the original golden brown color, use a transparent, penetrating oil-based sealer with UV inhibitors in a trans-oxide pigment tint and reapply annually, or as needed.

If you prefer a natural, silvery-gray appearance, use a clear oil-based sealer for the first coat and then simply let the wood weather to its natural gray color.

If you want to return silver-gray wood to the original color, use a “wood brightener.” Careful power washing and/or sanding can help to remove the grayed wood.

How does Cumaru decking material compare to other types of decking materials?

Compared to other types of decking, such as pressure-treated lumber, composite decking, or cedar, Ipe decking is much more durable and long-lasting. It also has a higher resistance to rot, decay, and insects, and is less likely to splinter or warp over time.

Is Cumaru wood resistant to termites and other pests?

Yes, Cumaru wood is naturally resistant to termites and other pests due to its high density and natural oils. The dense structure of the wood makes it difficult for insects to penetrate, while the natural oils in the wood act as a repellent to many types of insects and pests.

This makes Cumaru wood an ideal choice for outdoor projects such as decks, fences, and furniture, which are more susceptible to insect damage due to their exposure to the elements.

What is the cost of Cumaru decking compared to other types of decking?

The price of Cumaru wood can vary depending on several factors, such as the grade, thickness, and quality of the wood, as well as the supplier and location. However, in general, Cumaru wood is considered to be a mid-priced hardwood, with a cost that is higher than softwoods such as pine and cedar, but lower than high-end hardwoods such as teak or mahogany.

Compared to other commonly used hardwoods, such as oak, maple, and cherry, Cumaru wood is generally priced higher. However, it is still more affordable than other exotic hardwoods such as ipe, teak, or ebony.

Is Cumaru wood environmentally sustainable?

Cumaru wood is generally considered to be an environmentally sustainable option for hardwoods. This is because it is sourced from managed forests and can be harvested without causing deforestation or habitat destruction. Additionally, Cumaru wood is often harvested in a way that promotes reforestation and biodiversity in the region.

Is Cumaru fire-resistant?

Due to its high density and natural oils, Cumaru wood is naturally fire-resistant earning a Class A fire rating, which is the highest possible for combustible materials. Cumaru is highly resistant to fire and will not easily ignite or spread flames. However, it is still important to exercise caution when using any type of wood around fire, as excessive heat and flames can still cause damage and create a fire hazard.

Can I install Cumaru deck boards myself?

Yes, Cumaru deck boards can be installed by DIY enthusiasts who have experience with woodworking and basic carpentry skills. However, it is important to note that Cumaru wood is dense and heavy, which can make it challenging to work with. It is recommended to use specialized tools and fasteners that are designed for hardwoods to ensure a successful installation.

BETTER TOGETHER

Fastening Systems

We make fastening easy. Iron Woods decking can be installed using the EB-TY Hidden Deck Fastening System, the Starborn Color Matched Pro-Plug System, or Iron Woods Boardwalk and Deck Screws.

Go ahead. Dream a little.

How will you make your corner of the world beautiful? Here are some projects to get you started.

Your next project begins with Iron Woods. Let’s get started.

Tell us what you’re looking for.

Your next project begins with Iron Woods. Let’s get started.

Tell us what you’re looking for.